Product Description

1.Product information

a.)Jinan Datong Machinery base on the market demand,to do R&D of fish food production line for various models and settings.By adjusting raw materials,temperature,moisture and other technical parameters, to make our products with characteristics of unique shape, elegant texture, plenty of nutrients, suitable for the usage of different kinds of fish.

b.)Fish feed production equipment made by Datong company can produce various kinds of floating fish food,sinking fish food, by adjusting the degree of extrusion, can control the floating time in water, in order to produce high quality specialised fish food, in order to adapt various kinds of fish. Furthermore, this fish food production line can be widely used to produce dog, cat, bird and pet food production.

c.)Fish food production line process flow:

Raw material preparation→Mixing raw material→Conveying→Extrusion→Conveying→Drying→Screening→Oil spraying→Flavoring→

Packing

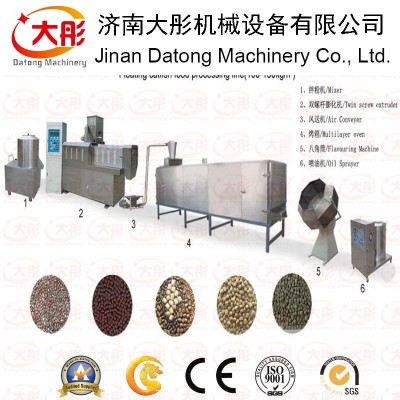

d.)Fish food production line setting:

Mixer→Conveyor→Extruder→Wind conveyor/hoister→Multi-layer dryer→Sifter→Hoister→Oil sprayer→Single/double roller→Packing machine In some cases,the production need to mill, and can adopt:Mixer→Conveyor→Extruder→Crusher→Packing machine

2.Formation of fish food production line:

1 )Mixer:There are 3 machine model numbers to choose from base on the production capacity.

2 )Conveyor:To convey raw materials to the extruder machine

3 )Extruder machine: To choose DSE model extruders base on the production capacity requirement from 100kg per hour to 3ton per hour. The raw material include corn powder, cereal powder, soybean powder, shrimp powder and so on. Size of the pellet depends on the moulds. The pellet size our machine can produce are 0.5mm, 1mm, 2mm, 3mm, 4mm, 5mm,6mm.

4 )Hoister: Convey the fish food to the dryer, the height of the hoister depends on the dryer.

5 )Multilayer dryer:Electric dryer, controlled by control box, temperature range 0-200ºC.Inside is stainless steel double layer mesh net. Drying time is adjustable according to speed. We have dryers of 3 layer 5 meter, 5 layer 5 meter, 5 layer 7 meter, 5 layer 8 meter, 7 layer 8 meter, and 5 layer 11 meter steam dryer.

6 )Sifter:To remove scrap

7 )Flavoring line: To spray oil and phagostimulant, the equipment are: single roller, double roller, round roller. Varies depends on the different production line setting, to spray oil to the surface of the product and make it even.

8) Cooling conveyor: To lower the product temperature in order to pack it easily.

9 )Sifter: To remove the wasted material and ensure quality, meanwhile to ensure the reuse of materials.

10 )Packing machine: Manual and automatic packing machine.

3.fish food making machine specifications:

Model | Installed power | Real power | Output | Dimension |

| SLG65 | 70kw | 40kw | 100-150kg/h | 22000*1200*2200mm |

| SLG70 | 90kw | 50kw | 200-240kg/h | 25000*1500*2200mm |

| SLG85 | 120kw | 100kw | 400-500kg/h | 30000*3500*4300mm |

| SLG90 | 135kw | 100kw | 800-1000kg/h | 30000*3500*4300mm |

| SLG95 | 165kw | 115kw | 1000-2000kg/h | 30000*3500*4300mm

|

4.Company Information

Jinan Datong Machinery Co., Ltd is a professional food machinery manufacturer in Jinan city shandong province China.Our company congregates an exceptional food machine engineering team, personal customer service center and high quality manufacturing capabilities have evolved exponentially,We are working hard on explore constantly not only in the research of extrusion technology, but also in food technics to benefit our clients producing newfangled food in their markets. It making us become one of the preeminent providers of reliable extrusion equipment.

5.Packaging & Shipping

A.)Packing: Simple packing stretch film (Based on the customers' need adopt the wooden case or wooden pellets, etc.)

B.)Transportation: We will choose the most timely and safe way transportation.

6.Service

1). Free consultation service before, during, and after sales;

2). Free project planning and design services;

3). Free debugging of equipment

4). Free management of equipments' long distance shipping;

5). Free training of equipment maintenance and operating personally;

6). Free new production techniques and formulas;

7). Provide 1 year complete warrantee

7.FAQ

1. )Q: Are you a trading company or a manufacturer?

A: We are the manufacturer, which has many years of experience in this industry.

2. )Q: How can I get to your company?

A: That's great you can visit our factory, welcome! You can get a flight to Jinan Airport. We are so glad to arrange our car pick you up!

3.) Q: How long is your guarantee?

A: One year(Calculated from the equipment arrives the customer's side.).After this period we will definitely support you when needed.

You will be welcome to contact us with any problem may happened.

4. )Q: Will you send engineers to install the plant?

A: yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.

Fish food processing line, fish food processing machine, fish food machine, fish feed machine, fish food extruder, fish feed extruder, floating fish food processing line, floating fish food extruder, catfish feed machine, catfish food production line, Tilapia food making machine, fish food pelleting extruder, fish feed extruder machine, floating fish food processing line, floating catfish feed machinery

Welcome your consultation.

English

English