Quick Details

Place of Origin:

China (Mainland)

Product Description

Basic Info

- Model NO.: SLG90

- Processing Object: Cereals

- Screen Mesh: Without Screen Mesh

- Pellet Mill Type: Screw Granulator

- Expanding Method: Wet Expansion

- Applicable Materials Shape: Powder

- Line Size: 50*5.*6.0

- Inverter: Delta Brand

- Electric Parts: LG, FUJI, Omron etc

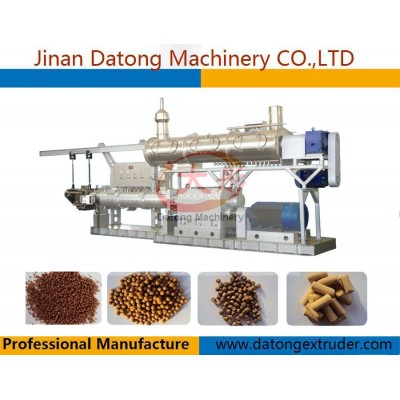

- Name: Fish Feed Pellet Food Machines

- Transport Package: Woodcase

- HS Code: 843880000

- Type: Pellet Mill

- Processing Technics: Crushing-before-Mixing

- Grinding Equipment Type: Roll Crusher

- Bulking Machine Type: Twin Screw Bulking Machine

- Condition: New

- Material: Stainless Steel

- Motor Brand: Siemens Brand China Brand

- Fish Food Types: Floating Types

- Capcity: 100-150kg/H

- Trademark: Jinan Datong Machinery Company

- Origin: Jinan

Product Description

Aquaric Fish Feed Production Line:

1.Our fish Food Making Machine Pet food Processing Line also may be referred to animal feed machine, pet food machine, shrimp feed extruder and so on, which is widely used for producing grains into high-grade aquatic feed pellets for:

A. Aquafeeds--- The fish feed pellet can make sinking fish feed pellets and other kind of aquatic feed .The fish feed pellet is 0.9-20mm size, you can choose the size you prefer.

B. Pet feeds---There have 9 shapes feed for your choosing, such as triangles, cross-shaped, square-shaped, feet shaped, large bone-shaped, small bone-shaped.All of these types feed pellet be made through changing the different shape molds.

2.Cat fish Food Making Machine Pet food Processing Line Raw materials:

All kinds of grains, such as bean, corn, wheat, etc. Some agricultural waste, such as rice husk, cotton stalk, cottonseed skins, weeds, crop stalks and other plant wastes, especially unformed materials.

3.Pet food shapes/sample

As long as you change the extruder mould to get different shapes. like bone,heart,pellet,fish,traingle......

4.Fish Food Making Machine Pet food Processing Line process flow:

Raw material preparation→Mixing raw material→Conveying→Extrusion→Conveying→Drying→Screening→Oil spraying→Flavoring→Packing machine.

5.Fish Food Making Machine Pet food Processing Line setting:

Mixer→Conveyor→Extruder→Wind conveyor/hoister→Multi-layer dryer→Sifter→Hoister→Oil sprayer→Single/double roller→Packing machine

Drive Motor:55.0kw;

Feeding:1.5kw;

Oil-pump: 0.37kw;

Cutting: 1.5kw;

Output:800-1200kg/h

Dimension: 5000*850*1750mm

2.Pet food dryer:

1. This dryer has the compact structure, small occupying, large drying area, small surface area, slight radiating heat and high thermal efficiency.

2.The belt and the heat preservation use the stainless steel; it is suitable for food safe industry level.

3.The running speed of belt net can be controlled (frequency controlling system)

4.The temperature can be controlled willfully and designed according to the need.

Nitriding treatment(120 Hours)

Depth of Nitrided Layer: 0.5-0.8 mm

Hardness of Nitrided Layer: 950-1100Hv (HRC56°-65°)

Chrome Plating

Thickness of Hard Chrome Plating Layer: 0.05-0.10mm

Hardness of Hard Chrome Plating Layer: ≥950HV

Bimetallic Screw: Plasma Alloy Coating Spraying

Depth of Bimetallic Layer: >2mm

Hardness of Bimetallic Layer: HRC55°-68°

Bimetallic Barrel/Cylinder: Centrifugal Casting (Inlay Alloy)

Depth of Bimetallic Layer: >2mm

Hardness of Bimetallic Layer: HRC55°-68°

Packing machine with woodcase and plastic flim

Loading container in our factory

Packing: inside plastic bag, outside wooden case for Extruded Food Wheat Corn Snack Pellet Making Machine (Based on the customers' need adopt the wooden case or wooden pellets, etc.).

Transportation: shipping, train, express or upon clients' demands.

1. Free consultation service before, during, and after sales;

2. Free Project planning and design services upon clients' special demands;

3. Debugging and inspecting of equipment until everything is functional before leaving the factory;

4. Overseas installation and training of equipment maintenance and operating personally;

5. Provide basic production techniques and formulas;

6. 1 year complete warranty for Extruded Food Wheat Corn Snack Pellet Making Machine.

8. Datong Company Fish food pellet making machine Technical Parameters:

Model |

Installed power |

Real power |

Output |

Dimension |

SLG65 |

70kw |

40kw |

100-150kg/h |

22000x1200x2200mm |

SLG70 |

90kw |

50kw |

200-240kg/h |

25000x1500x2200mm |

SLG85 |

120kw |

100kw |

400-500kg/h |

30000x3500x4300mm |

SLG90 |

135kw |

100kw |

800-1000kg/h |

30000x3500x4300mm |

SLG115 |

165kw |

115kw |

1000-2000kg/h |

30000x3500x4300mm |

Snacks Food Machine, Floating Fish Feed Extruder, Animal Food Making Machine manufacturer / supplier in China, offering New Catfish Feed Extruder Machine, Pet Dog Food Processing Machinery, Fried Niknak Corn Curl Kurkure Cheetos Snack Food Making Machine and so on....

View detail

Basic Information

Business Type:

Manufacturer

Factory Area (Sq.meters):

Supplier Assessment Report

Supplier Assessment Reports are detailed on-line reports about the supplier's capabilities. It helps you get all the information you need to trade confidently with suppliers

Send your message to this manufacturer

English

English