Waste plastic pyrolysis plant

Millions of tons of plastic waste pollute our world. If we can turn them into fuel? This is a very worthwhile discussion topic! In the past, this was an impossible goal, but now DoingGroup has developed a waste plastic pyrolysis plant, which is a closed and oxygen-free environment. Waste plastics are heated at a high temperature to obtain fuel, carbon black, and flammable gases after the cracking reaction.

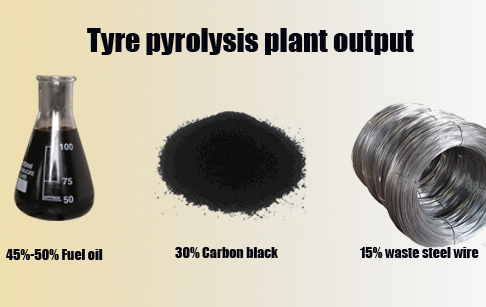

After this reaction, the fuel rate is 45-50%, the carbon black rate is 30%, and the combustible gas yield is 10%. This shows that it is technically feasible to convert waste plastics back into oil!

So, how can you turn plastic back into oil through the DoingGroup's plastic pyrolysis plant? In other words, DoingGroup's fee-based plastic pyrolysis plant is the specific operation process!

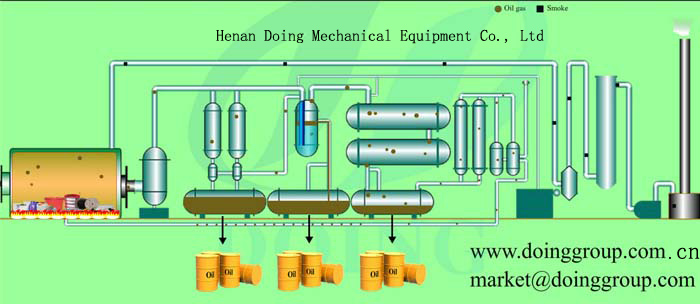

1. Pass the waste plastic through the automatic pushing device and send it to the reaction vessel.

2. The reactor is heated and the temperature reaches a certain level. The waste plastic begins to crack out of the oil and gas.

3. The cracked oil and gas enters the condensing system under the action of high and low pressure, and is liquefied into heavy oil and falls into the oil tank.

4. The waste flue gas and waste water produced during the combustion process are treated to achieve zero pollution to the environment. All kinds of emissions strictly comply with European and American environmental assessment standards.

5. The waste generated during the combustion process is automatically discharged from the furnace through the side slag discharge system.

DoingGroup is a professional manufacturer of plastic pyrolysis plant. From the initial stage of equipment development, it takes into consideration the important factors of EIA. The environmental protection control system mainly has the following aspects:

Waste water pollution control

The company's waste plastics pyrolysis plant, whether it is cooling water or dust water, uses recycled water to ensure zero discharge of waste water in the production process.

1) Cooling water, tubular condenser design, oil running inside the pipe, and water running outside the pipe. Zero contact with water and oil, cooling water can be recycled without emissions.

2) Dust out water, adopt professional water film dust collector. The three-layer high-pressure spray technology, can ensure that the solid small particles in the smoke are fully washed; the recycling of dust can be realized.

Waste smoke pollution control

If the fuel is coal, firewood or heavy oil, the amount of smoke is large, you can also choose to use pulse type dust collector. The pulse dust collector is a dry dust collector and does not require water, so there is no moisture emission.

Waste gas pollution control

The main source of waste gas and the tail gas produced during the production of oil refining, in addition to some of the non-condensable gases that can be directly used to heat the reactor, there is also a small amount of contaminating gases. In response to these small amounts of contaminating gases, DoingGroup launched a desulfurization and odor removal tower system, which is specially used to remove H2S gas, and some NOx, COx, gases, helping customers thoroughly solve the problem of difficult to achieve environmental impact assessment. Customers have been well received.

It is concluded that the change of waste plastic to oil is also feasible in handling relevant environmental assessment procedures!!!

At present, the technology for converting waste plastics into oil has matured.Pyrolysis plant has a broad market prospect and a professional environmental protection control system to ensure that you can easily handle relevant environmental assessment procedures. This is a very worthy investment industry. , will bring you huge profits!!!

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.continuouspyrolysisplant.com