Lubricant is used in various types of vehicles, machinery and equipment to reduce friction, protection of machinery and machining parts of the liquid or semi-solid lubricants, the main lubrication, auxiliary cooling, rust, cleaning, sealing and buffering role. In 2016, the lubricating oil consumption in China was 7 million tons, increasing by 3% -5% annually. With the increasing oil, resulting in more and more waste lubricating oil.These waste oil generated on the soil and water quality have a great pollution, but after the scientific assessment of waste oil recovery rate is as high as 80%. In response to this social problem, DoingGroup has developed waste oil refining equipment.

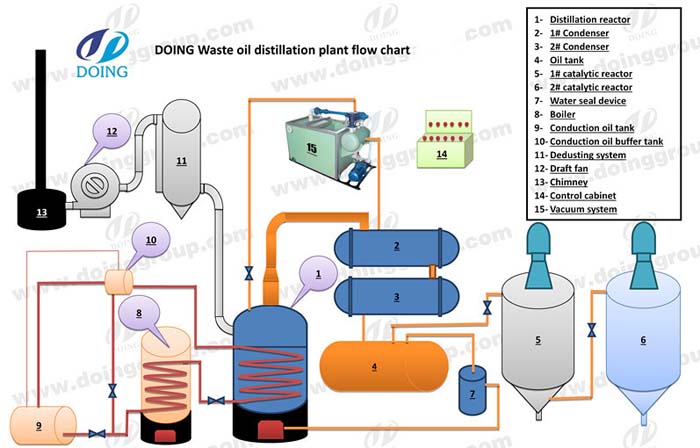

The main work flow of waste oil refining equipment:

1. The waste oil into the tube heating furnace heating.

2. Distillate the oil vapor through the distillation process

3. Oil vapor through the condenser, fractionation of the base fuel oil

4. After sedimentation filtration, adding decolorizing agent, reconcile to become qualified fuel oil.

Waste oil refining equipment advantages:

1. Reactor with vertical design, compared to my reactor, easier slag discharge.

2. Using base heating and thermal system double heating system, heating fast, short time.

3. Large capacity, can be customized according to the needs of production equipment.

Waste oil refining equipment final products:

Disel oil usage

1. Diesel oil:Mainly used in heavy machinery,generatror,boiler.

2. Asphalt:Mainly used in paving,refinery.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com