Waste plastic pyrolysis equipment

Plastic products everywhere, plastic bags, plastic buckets, plastic cups, plastic toys ...... Plastic products exist in all aspects of our lives, on the one hand the cost of plastic products is relatively low, on the other hand he can give us Life brings unlimited convenience and fun. However, due to its low cost, plastic products also have a drawback that a large amount of plastic products will be discarded and become household waste, which will endanger our living environment. In response to this social problem, DoingGroup, using thermal cracking principle, developed a waste plastic pyrolysis equipment. Of course, our equipment is not only used to deal with waste plastics, but also for the disposal of waste tires, waste rubber.

Waste tire pyrolysis equipment working process

Pyrolysis, refers to the pyrolysis of organic matter in an oxygen-free environment, and is a chemical process that converts one sample to another. Waste plastic pyrolysis equipment is the process of pyrolysis of waste plastic into oil, non-condensable gases and carbon black and steel wire by heating at high temperatures.

Running our equipment can earn nearly a million RMB everyday, mainly from the fuel and carbon black cracked from the waste plastic pyrolysis equipment after high temperature heating, and combustible gases. These substances have very important uses in our life, so we can create huge profits for us.

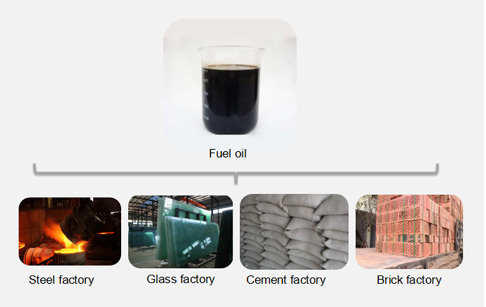

Fuel oil application

Fuel oil: Mainly used in steel plants, boiler heating, heavy oil generators, cement heating oil. If you refine these oils out of the refined diesel, but also for diesel generators, light fuel, heavy machinery.

Carbon black: mainly used for pressure ball burning and refining flour. Which refined flour and can be used for new tires, rubber soles, pigments of raw materials.

Combustible gas: will be recycled equipment, re-used for reactor heating.

The choice of our equipment will give you an exact guarantee of your profit based on the unique advantages of our equipment. These benefits are as follows:

1. Our pyrolysis reactor is manufactured according to pressure vessel production standards using a 16mm thick boiler special steel and arc head that withstands high pressures and temperatures.

2. High standard 3-step welding process, not easy to crack, long service life.

3. Pinion rotation device, small power, does not directly contact the reactor, heat transfer less easily deformed.

4. The three-stage cooling system uses tube condensers, also known as heat exchangers, which are currently the most commonly used and best performing condensers in the oil industry. Can ensure that the cracked oil and gas fully cooled, high oil production.

5. Our equipment has the following safety devices: water separator, water seal, vacuum device. They prevent oil and gas backflows. Provide negative pressure, drainage oil and gas, so as to maximize the oil yield.

After the above introduction, do you also have a great interest in our waste plastic pyrolysis equipment? Any equipment problems, please feel free to contact me! !

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com