Waste plastic pyrolysis equipment

In industrial and consumer applications, the growing problems of environmental pollution and the utilization of plastic and rubber waste, coupled with the growing demand for fuels and energy, have led to increased demand for solutions that convert plastic and rubber waste into energy for production And a reusable entity. One of the fastest growing industries is recycling through pyrolysis because the waste plastic pyrolysis equipment not only saves the environment but also provides alternative sources of energy without affecting natural resources. It also proposes to use waste rubber or plastic to produce fuel oil, which is an important industrial fuel.

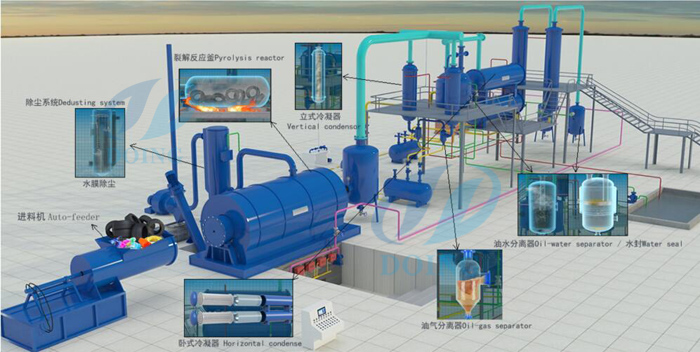

Waste plastic pyrolysis equipment manufacturing process

• Pyrolysis is a process that processes rubber and industrial waste plastics to decompose organic compounds in anaerobic environments to produce gases, oils, and other useful products.

• Waste rubber or plastic is filled into the reactor vessel and heated under controlled temperature and anaerobic conditions.

• Therefore, gaseous oil is produced with other gases. These gasified gases pass through the heat exchanger, where the gas condenses into a liquid form. The heat exchanger uses water as the condensing medium, and this water is recycled from the cooling tower back to the condenser.

• In the process, carbon black can be used for different purposes.

• Non-condensable gases are used again to maintain the reactor temperature.

The advantages of waste plastic pyrolysis equipment are as follows:

1.Turn waste into treasures

Plastic pyrolysis is DoingGroup's latest technology. It converts pyrolysis plastics into pyrolysis oil, carbon black and combustible gases through pyrolysis chemistry. These converted substances have a wide range of uses in our life. At the same time, it is also very beneficial for our environmental protection due to the reduction of environmental pollution due to the reprocessing of waste.

2. High oil production rate

Our plastic pyrolysis can be used for 18 different raw materials and they will have different amounts of oil. Equipment with negative pressure device, can not condensate oil vapor circulation filter condensing system, so as to achieve the maximum amount of oil. After our many accurate measurements, the average oilfield output reached 60%.

3. Safety and environmental protection.

Our plastic pyrolysis units for sale are supplied with buffer tanks, vacuum units and water seals to ensure safe and efficient operation of the plant. Our plastic pyrolysis oil-water separator and dust removal equipment can effectively deal with the waste gas generated during the operation of waste equipment.

The wide range of uses of the waste plastic pyrolysis equipment product:

Fuel oil application

Fuel oil can be used in steel mills, boiler heating, heavy oil power plants and cement plants to produce refined diesel for further processing and diesel generators, light fuels, heavy machinery.

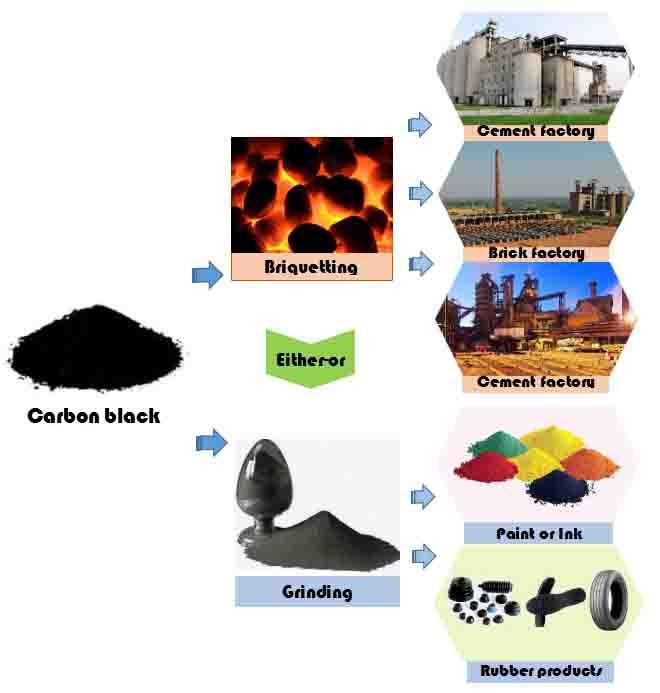

Carbon black application

2. Carbon black can be used for pressure ball burning, refined toner. Can be used for new tires, rubber soles, pigments made of refined toner.

We offer these plants different capabilities, sizes and specifications to meet a wide range of industrial requirements. Any problems about our waste plastic pyrolysis equipment, please feel free to contact us! !

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com