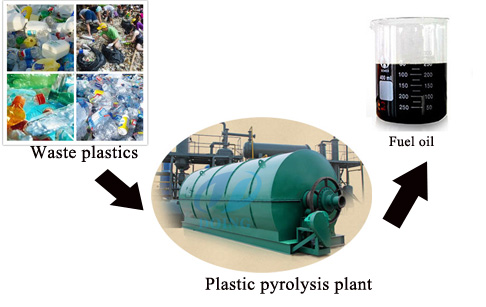

Waste plastic pyrolysis equipment

Waste plastic pyrolysis equipment using advanced technology and technology, in an efficient, safe and environmentally friendly, based on the realization of industrial production. The waste rubber, plastic waste catalytic reduction to liquid fuel, carbon black and a small amount of non-condensable gas.

Advantages of the waste plastic pyrolysis equipment:

1. Standard pressure vessel, Q245R standard boiler plate steel, the thickness of 16mm.

2. Seamless welding process, not easy to crack, long service life.

3.360 degree omnidirectional insulation cover, thermal insulation effect is more prominent.

4. A negative pressure, water seal device to ensure safe and efficient operation of equipment. And negative pressure equipment can increase the oil rate.

The main process of waste plastic pyrolysis equipment is as follows:

1, First of all, the waste tires from the feed door into the host reactor, close the feed door, sealed. Heat the main furnace with fuel coal or wood in the heating chamber.

2, When the temperature reaches 220 ℃, oil and gas precipitation, into the buffer chamber, residual oil (containing some slag) sink to the residue tank.

3, Light oil automatically enters the cooling system, condensed into oil.

4 Non-condensable gas, it will return to the reactor, as the heating reactor fuel.

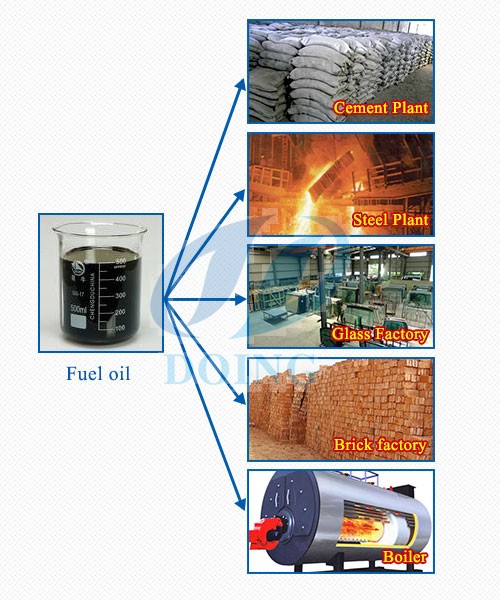

After the above process, you can get fuel, carbon black, combustible gas, these reusable materials, they have a wide range of uses, as follows:

Fuel oil application

Fuel oil can be used in steel mills, boiler heating, heavy oil power plants and cement plants to produce refined diesel for further processing and diesel generators, light fuels, heavy machinery.

Carbon black application

2. Carbon black can be used for pressure ball burning, refined toner. Can be used for new tires, rubber soles, pigments made of refined toner.

3. Combustible gas is mainly used for circulating heating reactor.

Are you interested in our waste plastic pyrolysis equipment, any equipment problems, please feel free to contact me !!

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com

English

English Español

Español Русский

Русский עברית

עברית Français

Français

Product quality protection

Product quality protection